In today’s fast-paced industrial and architectural world, the demand for high-performance, durable, and corrosion-resistant materials has never been higher. Traditional materials like mild steel or aluminum often fall short when exposed to harsh environments, chemicals, or long-term wear and tear. This leads to frequent replacements, higher maintenance costs, and unexpected project delays — problems no project manager or fabricator wants to deal with.

With 2025 seeing an uptick in infrastructure upgrades and clean energy projects, choosing the right material is more critical than ever.

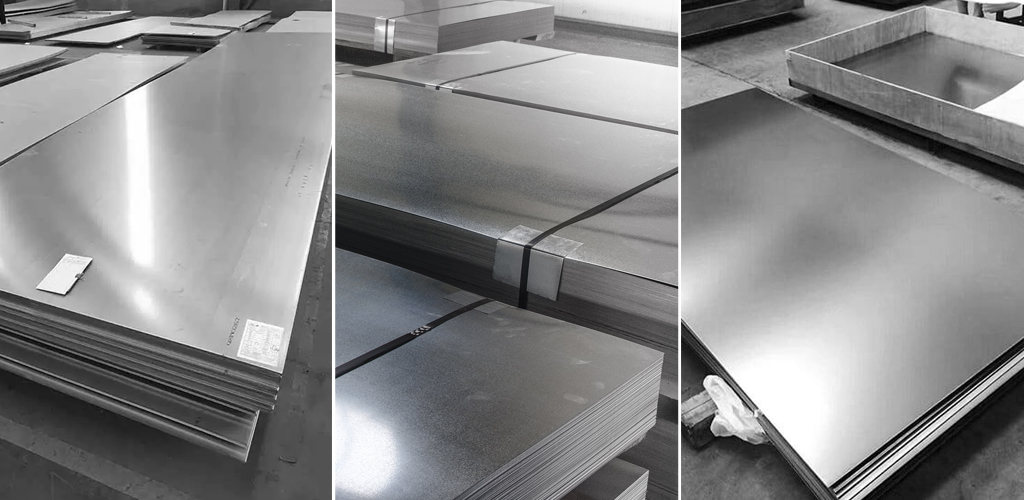

What Are Stainless Steel 304 Sheets?

Stainless Steel 304 Sheets are among the most widely used stainless steel products in the world. Made primarily of iron, with 18–20% chromium and 8–10.5% nickel, SS 304 offers excellent resistance to corrosion and oxidation.

Manufactured under global standards like ASTM A240 and ASME SA240, these sheets are designed for structural strength, hygiene, and longevity. As leading Stainless Steel 304 Sheets Manufacturers gear up for higher demand this year, the market is seeing increased availability in custom sizes, surface finishes (2B, No.4, BA), and gauge options to suit diverse applications.

Key Advantages of Stainless Steel 304 Sheets

- Corrosion Resistance: Ideal for marine and industrial settings due to high chromium and nickel content.

- Formability & Weldability: Easily fabricated into various shapes without cracking or deformation.

- Hygienic Properties: Perfect for food-grade applications, hospitals, and cleanrooms.

- High Temperature Resistance: Withstands temperatures up to 870°C, making it suitable for heat exchangers and boilers.

- Low Maintenance: Requires minimal upkeep compared to other metals, lowering long-term operational costs.

- Aesthetic Finish: Available in polished or brushed surfaces, lending a modern look to interior design and architecture.

Real-Life Applications: Where You’ll See Stainless Steel 304 Sheets

- Kitchen Equipment: Sinks, countertops, and utensils in commercial and home kitchens.

- Medical Devices: Operating tables, surgical trays, and hospital cabinets.

- Automotive & Transport: Truck bodies, exhaust systems, and structural components.

- Architecture: Cladding, decorative panels, handrails, and building facades.

- Industrial Equipment: Chemical containers, tanks, and machinery components.

- Renewable Energy: Solar panel mounts, wind turbine components, and energy storage systems.

How Stainless Steel 304 Sheets Solve the Problem

By incorporating Stainless Steel 304 Sheets, industries effectively address the core issues of corrosion, hygiene, and mechanical durability. These sheets drastically reduce the risk of failure in aggressive environments and comply with strict health and safety standards. Whether used in construction or chemical processing, SS 304 sheets minimize downtime and enhance product life.

Outcome: Projects completed with SS 304 benefit from greater reliability, reduced lifecycle costs, and fewer service interruptions. In seasonal applications like winter-ready outdoor kitchens or weather-exposed railings, they perform flawlessly year after year.

Conclusion: Built for the Demands of Today and Tomorrow

With rising expectations in design, safety, and sustainability, Stainless Steel 304 Sheets prove to be an unmatched solution. As trusted Stainless Steel 304 Sheets Manufacturers continue to innovate, the 2025 construction and manufacturing trends point toward increased adoption of this versatile material.